How to Control Industrial Noise?

March 14, 2017

Noise is a widespread hazard in factories, especially when it comes to the pulp & paper and metal & mining industries. Loud noise can be the source of both physical and psychological stress, reduce productivity, interfere with communications and concentration and even contribute to workplace accidents and injuries. Exposure to high noise levels may even cause acoustic trauma and permanent hearing loss.

ENGINEERING CONTROLS TO REDUCE NOISE

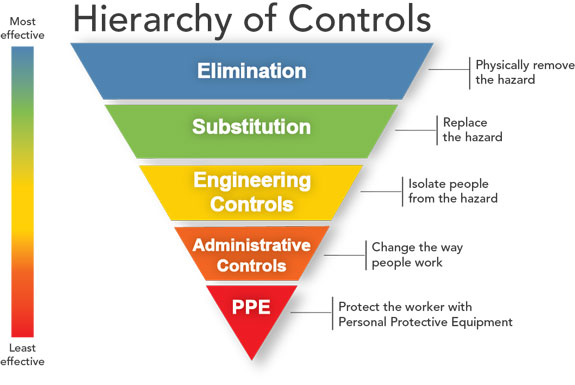

This picture shows the hierarchy of controls used by occupational safety and health professionals to determine feasible and effective ways to control noise hazards: elimination, substitution, engineering controls, administrative controls and PPE.

In manufacturing facilities, although it is common knowledge that noise can be harmful to workers’ health, the first and second options, elimination (physically removing the hazard) and substitution (replacing loud equipment for a quieter one) is sometimes impossible. Which brings us to the third option: engineering controls. This solution involves making physical modifications to control the hazards or to reduce exposure. In this article, I will focus on the third option for reducing noise with my expertise in designing modular buildings and enclosures.

-1- Can the workers be enclosed from the noise?

If employees can be isolated from the source in a room or booth, the other option is to acoustically treat the space where the employees work.

With automation of machines and processes, sometimes employees can control operations from a remote separate room. An insulated separate room is most practical for job activities such as product inspection or equipment monitoring stations, where employees spend a significant portion of the workshift inside the shelter. An acoustical booth, shelter or control room is used to isolate the employees from the noise and provide a relief from excessive noise levels. These kind of shelters can also be engineered against other hazards, such as vibration, blast, chemicals, dust, heat, etc.

Here again, openings are the weak spot of soundproof control rooms. Windows, doors, the heating, ventilation and cooling systems, and any hatches must be designed and sealed according to the required acoustic performance to avoid sound leakage. Silencers or attenuators are used for air inlet and outlet to stop noise from entering the cabin through the ventilation system.

-2- Can the noise be enclosed?

If the source of noise can be isolated in an insulated room or enclosure (such as a piece of equipment or machinery), an acoustic enclosure might be the best solution.

An acoustic enclosure is a closed engineering structure, designed and built for the purpose of reduction, minimisation, or attenuation of the noise generated by a particular piece of equipment or machinery. It forms a box around the said equipment and includes acoustic doors and windows and an attenuated ventilation and cooling system. It is often made of steel panels and noise absorbing material. The enclosure can also be equipped with a vibration dampening system in the presence of structure-borne noise.

The advantage of this solution is in avoiding making major modifications to the noisy machine and in its long-term investment since the enclosure remains efficient over time. Good quality enclosures can last more than 25 years without maintenance.

Ideally, the acoustic enclosure must be entirely sealed in but in reality functional openings such as the ones below, are often needed. However, each opening reduces the enclosure’s acoustic performance as openings are a way out for noise. For this reason, openings are carefully computed in the engineering of the enclosure and must be conducted by an acoustic professional. Using enclosures as a noise engineering control solution can reduce noise up to 55 decibels and even reach 70 db.

- Acoustic tunnels for the entrance of semi-finished material and the exit of products

- Access doors

- Access hatches for maintenance

- Observation windows

- Input and output of fluids and energies

- Inlets and outlets for de-dusting and ventilation

Applications: Generators, compressors, pumps, process equipment, presses, etc.

We can classify enclosures in 3 different types: Integrated, Complete, Partial

In an integrated one, the enclosure is close to the machine and operators cannot get inside. In a complete enclosure, the enclosure is bigger than the machine and workers can enter the enclosed space. A partial enclosure is incomplete, meaning the ceiling or certain walls are not acoustically isolated.

Here are two examples:

Integrated Enclosure

This acoustic enclosure for a metal press machine achieves a noise reduction of about 35 dB. The enclosure is also equipped with a ventilation system with fresh air intake and air conditioning. The sliding doors of 11′ by 8′ are entirely custom made.

Partial Acoustic Enclosure

The partial acoustic enclosure with two motorized doors as seen on this video was custom designed to match the shapes of our client’s machine. Once installed, the enclosure’s 3 sides and partial ceiling will fit tight against the machine and achieve an acoustic reduction of STC-35. It also includes a silencer for the air inlet and a LED lighting system.

Do you have a similar issue in your plant?

MECART modular buildings are custom-made to your needs. Our team of experts can find solutions to any challenges your project might be facing. The more difficult the challenge, the more fun we have solving it. Contact us and we will be more than happy to see how we can be of help with your project.